About Us

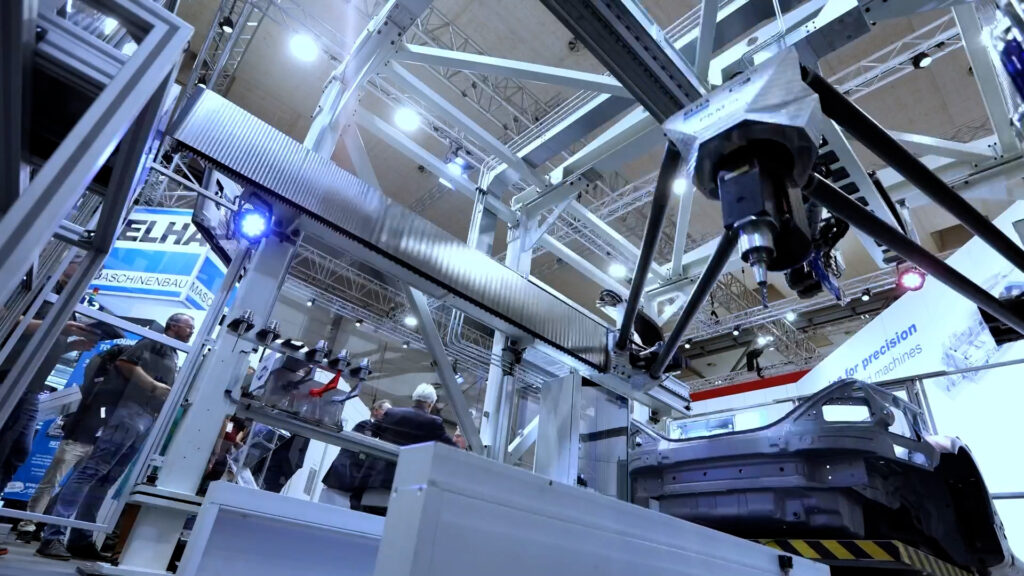

ELHA-MASCHINENBAU Liemke KG was founded around 1930 as a shop for electrical equipment. Later on ELHA started developing and building machine tools for the local woodworking and metalworking industry.

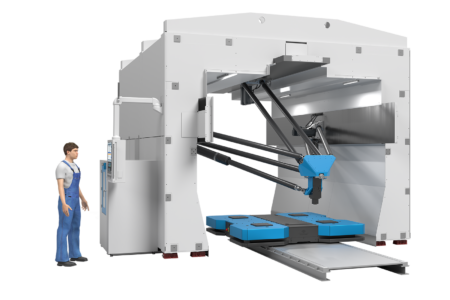

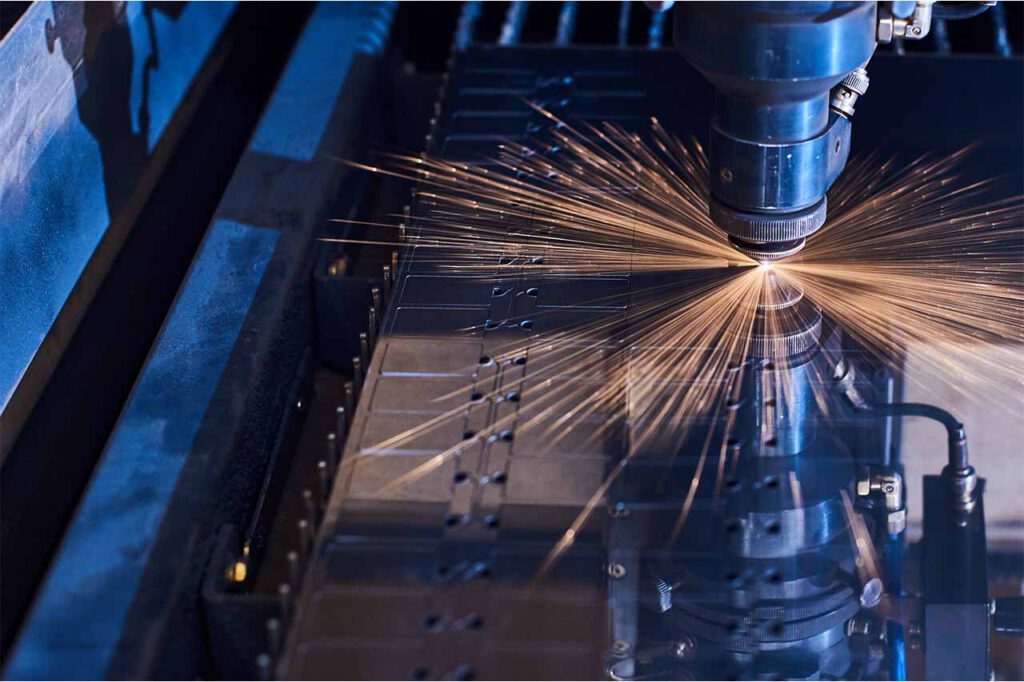

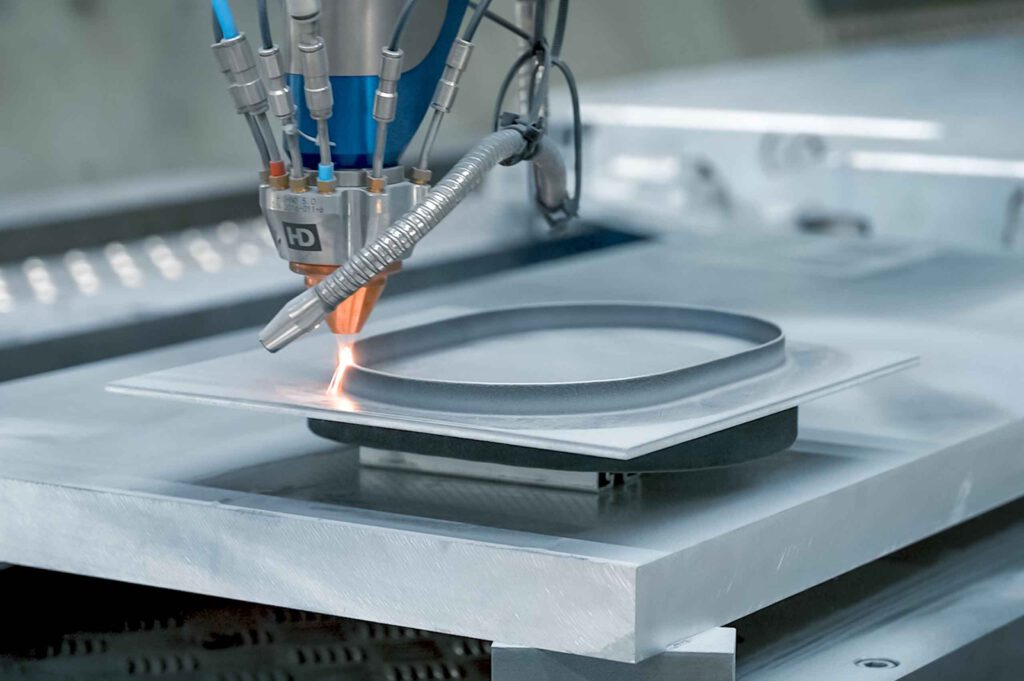

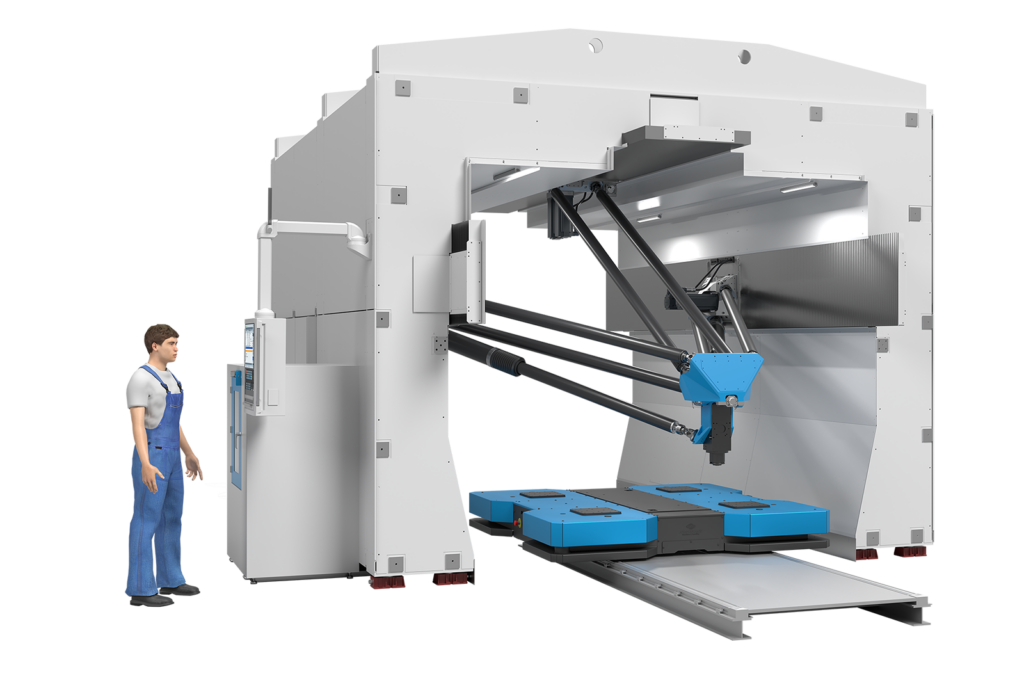

Today ELHA is known for customized machining centers, special machines and production modules. Our employees are the heart of the company, as they are always looking for new innovations to increase the productivity of our customers.