Our technology

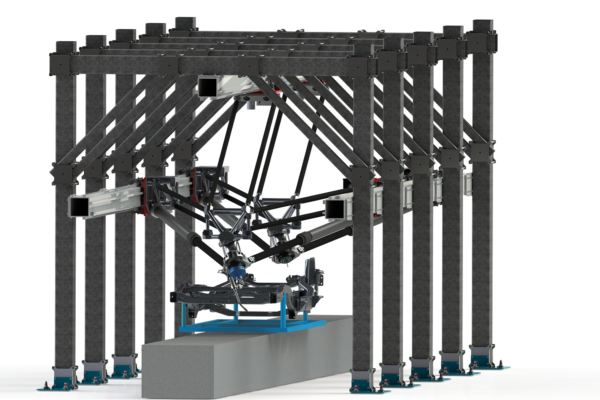

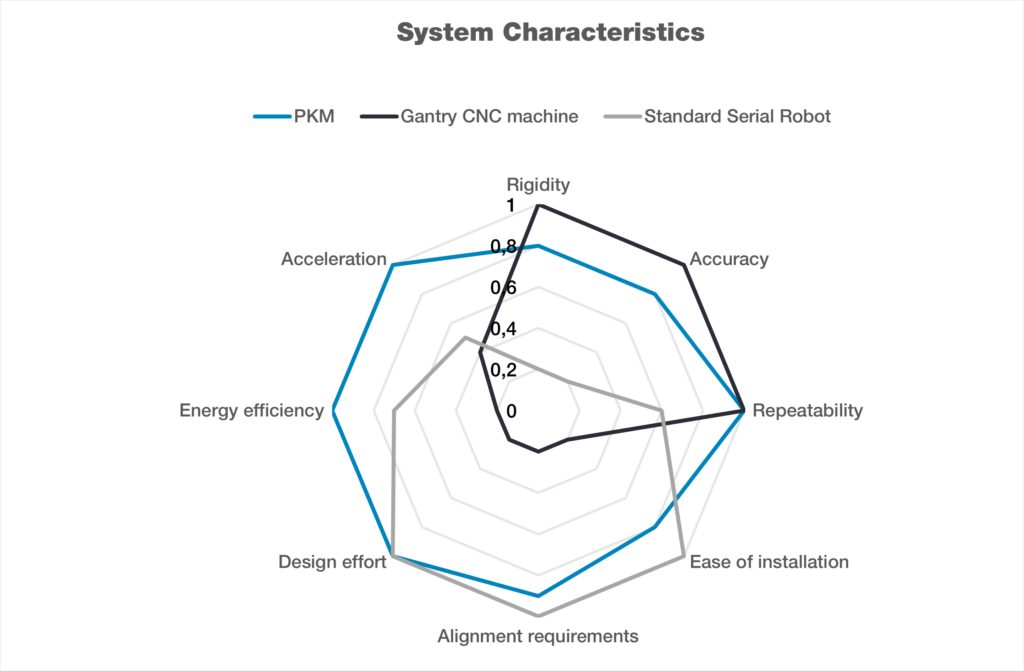

Parallel kinematic machining centers meet the highest requirements for rigidity and agility and turn visions into reality. By using parallel kinematics, our robots combine low weight and high speed. Through completely new design, the new robot concept achieves unimagined speed with the highest precision and flexible installation space.

Your Advantage

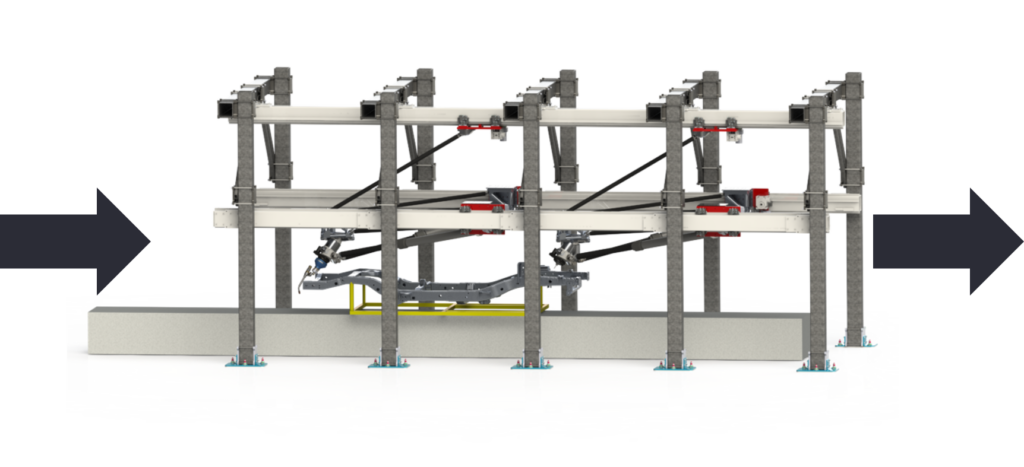

InLine processing machines from ELHA based on the PKM concept combine the advantages of classic CNC machines and flexible robot processing. A wide variety of components, including large castings, can be machined directly „inline“ with unprecedented precision and flexibility.

Product facts

- Paralel Kinematic Robots and Environment made by ELHA Maschinenbau Liemke KG

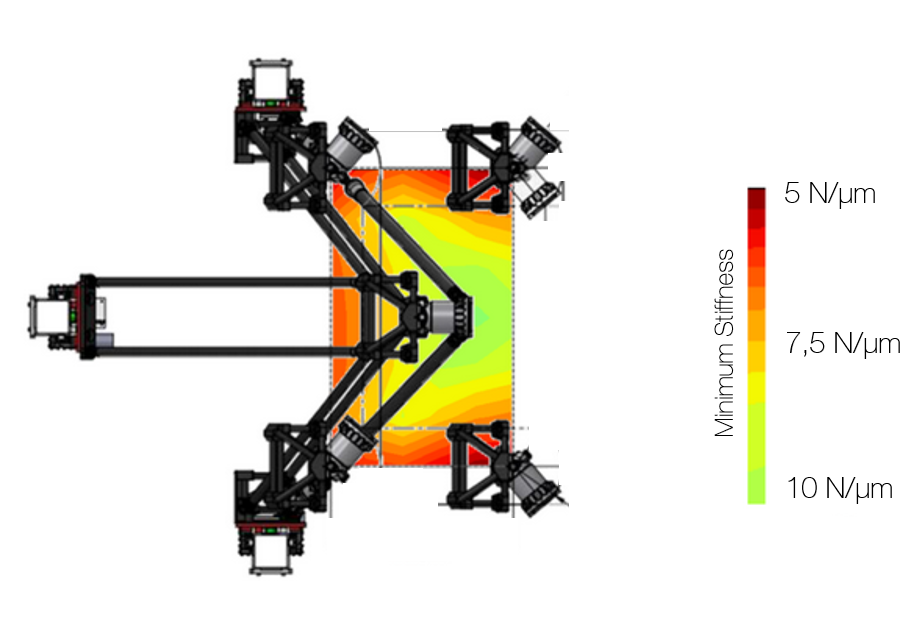

- High accuracy and rigidity over large workspaces, unlimited X-axis expansion

- High-dynamic and high-force configurations

The Parallel kinematic platform enables ELHA to quickly and efficiently design and build powerful machine solutions for large work areas.

It is a modular system that can be easily integrated into existing production lines and easily expanded into a multi-robot machine solution. This can also be added after the initial installation.

One or more robots can be mounted in any orientation of the working plane and can be adapted to the given working area.

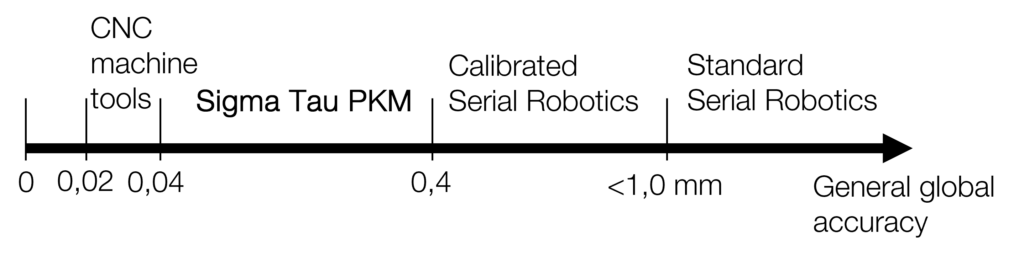

The Parallel kinematic concept achieves higher accuracy and rigidity compared to a traditional robotic arm manipulator, while retaining many of the flexibility aspects.

Technical data

| Max. Velocity | 170 m/min |

| Nominal Velocity | 100 m/min |

| Nominal Acceleration | 20 m/s² |

| Max. Payload | 500 kg |

| Nominal Payload | 40 kg |

| Axial Force (Fz) | 6 kN |

| Radial Force (Fr) | 6 kN |

| Max. Velocity | 68 m/min |

| Nominal Velocity | 40 m/min |

| Nominal Acceleration | 6 m/s² |

| Max. Payload | 500 kg |

| Nominal Payload | 120 kg |

| Axial Force (Fz) | 15 kN |

| Radial Force (Fr) | 10 kN |

We offer industrial robots from well-known manufacturers. We equip the automatic motion machines with unique grippers, production equipment or tools so that they meet your requirements exactly.